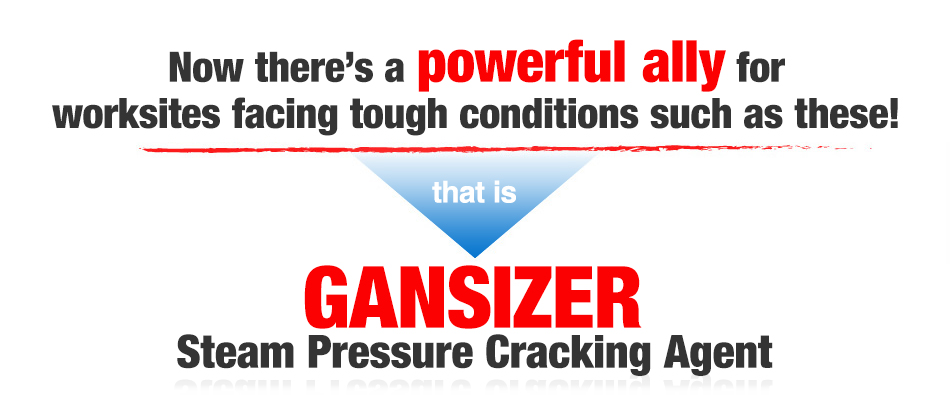

Needs such as these are being felt in construction sites throughout the country.Confronted by bedrock. Unable to use explosives. Construction periods dragging out. Safety. Cost reductions.

GANSIZER, a non-explosive, low vibration, steam pressure cracking agent from Nippon Koki Co., Ltd., can be used not only for limestone and quarry excavation and civil works such as dams, tunnels, and land formation, but also in situations such as building scrapping-and-building and urban redevelopment, where there are vibration and noise restrictions to protect the surrounding environment. GANSIZER is a steam pressure cracking agent that efficiently cracks while meeting these vibration and noise restrictions, helping shorten construction times and reduce costs.

Not an explosive!

GANSIZER is a revolutionary cracking agent which cracks hard bedrock through steam pressure produced by chemical thermal decomposition. It contains no explosives, so it is not covered by the Explosives Control Act, and requires no troublesome usage permits. It can be used easily whenever you need it.

Cracks instantaneously!

GANSIZER is different from static cracking agents. It is used by connecting an ignition tool and performing chemical ignition, making it possible to complete crack work quickly and on the spot. There are no wait times. Work can be carried out smoothly, shortening construction times.

Low vibration! Safe!

GANSIZER doesn’t generate the shock waves that regular explosives do. It only produces 1/2 to 1/5 the vibration of conventional explosives. It is a highly safe cracking agent which can be used for cracking work near homes, buildings, and roads

Helps reduce construction times!

Usage effectiveness evaluation by the New Technology Information System (NETIS) arrived at the following conclusions.

GANSIZER is not an explosive, but it can instantly crack objects, shortening construction times in comparison to conventional techniques.

- GANSIZER offers the workability of explosives, but requires no usage permits, so it is effective for buildings for which the use of explosives is prohibited for security reasons.

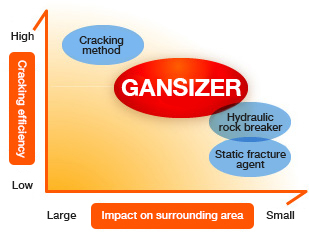

Also solves issues faced by other cracking methods

Explosives are generally used as a large-scale civil work and cracking method, but various other methods have now been developed, such as cracking using large breakers, ripping to perform large-scale rock excavation in outdoor work, and rock breaking using hydraulic wedges. However, these methods have limited levels of efficiency and application scopes, creating construction time and cost problems. GANSIZER solves these problems.

Examples of use in actual work sites!

GANSIZER is used in construction work ordered by Ministry of Land, Infrastructure, Transport and Tourism Regional Development Bureaus and individual prefectures!It has been used in over 500 worksites!

Dangerous rock removal | Cutting | Road bed lowering | Trench excavation | Deep foundation excavation work | Concrete disassembly, and other rock and concrete cracking work

User feedback

Residential construction work prime contractor

We were working near homes, so we couldn’t use blasting because of the vibration and noise it produces, and the rock we were working with was hard, so using a breaker would take too long. With GANSIZER, we were able to crack hard rock without receiving any vibration or noise complaints from those living nearby.

Deep foundation excavation work prime contractor

We were working in a cramped site, so we couldn’t bring in heavy equipment, and it would take too long to break up hard bedrock using compact equipment. GANSIZER was a tremendous help, enabling us to perform cracking.

National road improvement work prime contractor

Our national road improvement work was performed adjacent to existing national roads, so we were unable to use blasting, and rock breaking took too long. We used GANSIZER to improve excavation efficiency, reducing both construction time and costs.

Levee removal work prime contractor

We considered performing our work using static fracture agent, but we went with GANSIZER instead. We had initially planned for 30 days for removal work, but we were able to finish in 10.

Used in restoration work following the Great East Japan Earthquake!

GANSIZER contributed to restoration work in disaster-struck areas by performing exceptionally in situations such as cracking levees which were knocked down and submerged as the result of the tsunami, and crack large boulders which fell due to the earthquake.

Gansizer Guidebook (technical materials)

◎ GANSIZER Catalog > Download

◎ IC Multistage Igniter Catalog > Download

● Main Usage Track Record (April 2008 edition)

● Usage Case Collection

● Estimation Materials (March 2002 edition)

● GANSIZER Usage Vibration and Noise (June 2009 edition)

◎ Usage Manual (Ver. 2.0)> Download

● New Comprehensive Technology Materials (Ver. 1.2)

● Latest Usage Case Example “Shinkansen Area Deep Foundation Excavation Work”

● New Usage Case Example “Performing Construction Using Multistage Ignition Tools - Slope Face Large-Scale Excavation”

※* Always read the materials marked with a “◎” before using GANSIZER.

※* Please contact us for the materials marked with a “●”

[Technology is registered in the Ministry of Land, Infrastructure, Transport and Tourism's New Technology Information System (NETIS). (No.KT-990072-V)]

[Certified as follows in the Public Works Research Center's Civil Material Technology - Technology Review Certification Report (Technology Review Certification No. 0101). (excerpt from the certification)]

GANSIZAR is a registered trademark of Nippon Koki Co., Ltd.

As used herein , ® denotes registered trademark status in the JAPAN only.